2-Day Expedited Shipping Only $14.95 - See Restrictions

Water Cooling Components - Tubing

Welcome back to the Component Series. We hope to help builders both new and old to understand their options when it comes to the components in their custom water loops. In this installment we’re going to take a look at tubing.

So you’ve followed along with us as we talked at length about all the major parts of your water cooling system and you’ve got all of those selected and your loop planned out. What’s going to join all of those amazing parts together? Tubing.

You’ve got a lot of options when it comes to tubing – maybe more than you thought. Let’s take a look at the different kinds of tubing available.

Flexible or Rigid?

The first choice to make on your tubing is whether you want to use traditional flexible tubing or some form of rigid tube. Both serve the purpose but offer some advantages and tradeoffs.

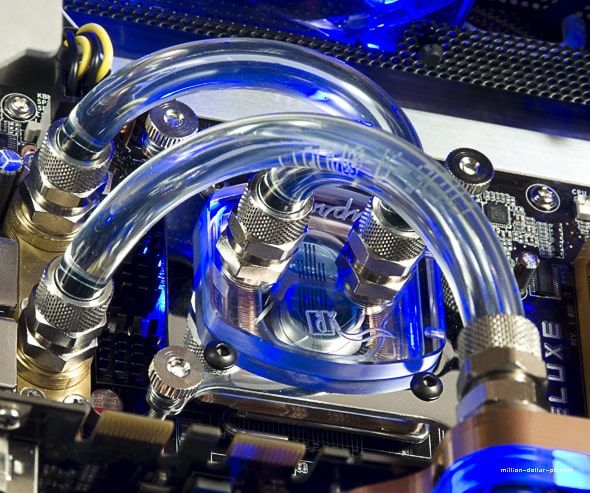

An amazing soft-tube water-cooling system. Image credit: Million-Dollar-PC.com

Pros:

• Easy to install

• Ease of loop maintenance

• Inexpensive

Cons:

• Some flexible tube can leach plasticizer into your water loop

• Lacks the aesthetic appeal of rigid tube

• Offers little to no physical support

Clear PVC soft tubing is a good choice for a clean and simple water-cooling loop.

The first advantage of flexible tubing is ease of use. It doesn’t require any special tools to bend or cut, angles don’t have to be painstakingly measured, and lengths can be measured and cut within a range of error since the flex of the tube itself will take up extra length.

This ease of use also applies to ease of loop maintenance. If a component in your water loop has to be serviced for some reason, removing the tubing is simple and quick. Component replacement can typically be done without having to replace the tubing going to it, and even it has to be replaced there are no painstaking measurements and bending to be done.

Flexible tube is less expensive than rigid tubing. In fact, depending on the material type, rigid tubing can cost many times as much as flexible tubing per meter. Even the most common forms of rigid tubing (acrylic and PETG) are often nearly twice the cost of common PVC flexible tubing. The fittings used for flexible tubing are also less expensive than their rigid-tubing counterparts.

Beautiful tight bends in flexible tubing. Image credit: Million-Dollar-PC.com

While soft tubing offers some excellent advantages over rigid tube, nothing is perfect.

Many types of flexible tubing utilize a compound called plasticizer to increase their flexibility. This is especially true in PVC tubing. Unfortunately, this plasticizer can break down over time, leaching out of the tubing material in the form of a fine powder. In serious cases, this powder can clog the tiny passages between the cooling fins in water blocks.

Advances have been made in plastics technology over the years that make today’s water-cooling tubing more resistant to plasticizer leaching and also given us some new material options like EPDM and TPV that don’t require plasticizers for flexibility.

Soft-tube loops can be made to look amazing and clean bends are entirely possible, but flexible tubing can’t be formed into the perfect combined straight and curved runs that can be achieved with rigid tube.

The flexibility of soft tube means that any load not supported by a fixed mount of some kind can cause the tube to sag or otherwise flex. Flow indicators are a good example. Rigid tubing will support these small loads without visible flex.

Size

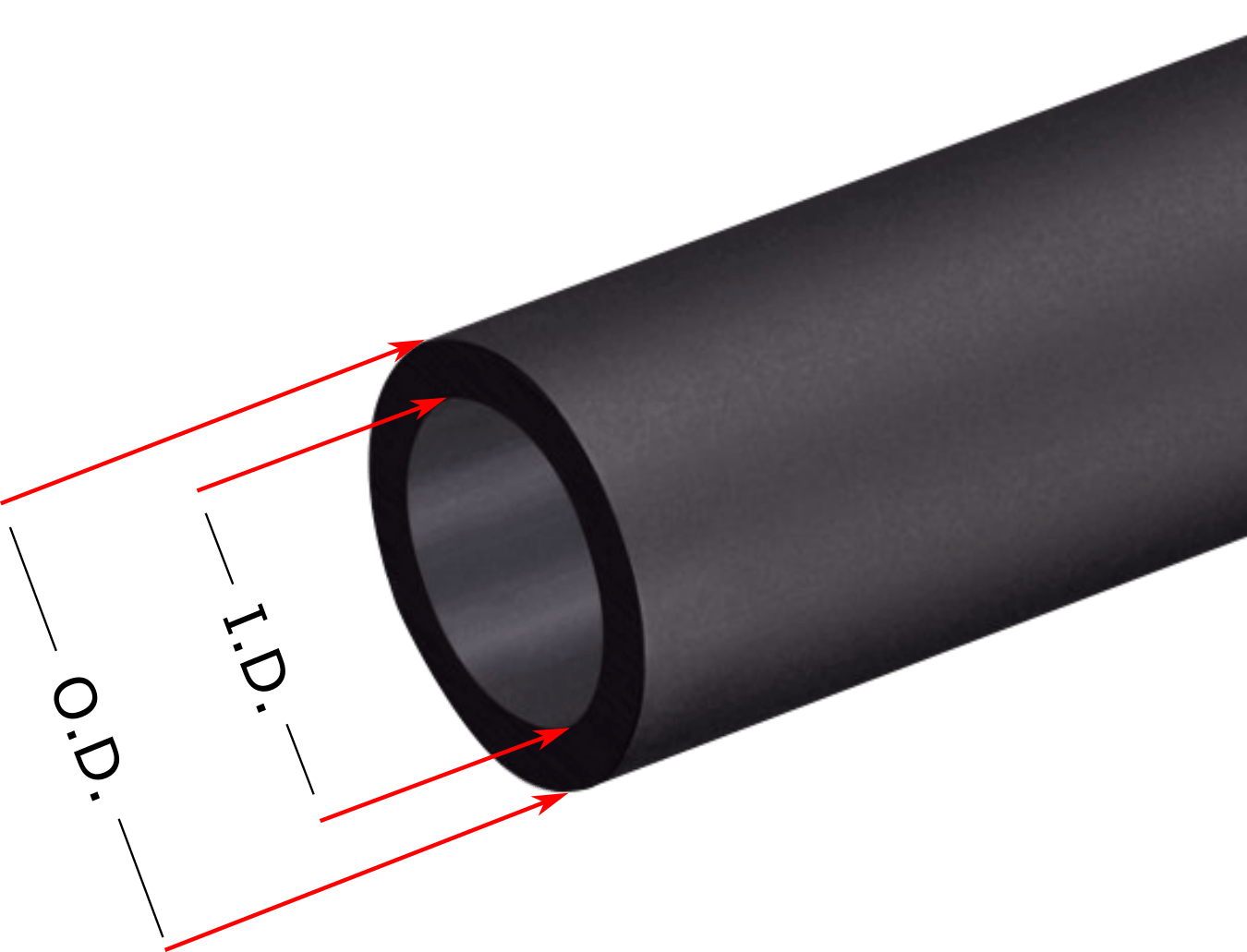

Flexible tube comes in a wide range of sizes. With soft tube it’s important to note that size is measured in both inside diameter and outside diameter (ID and OD). This is because the fittings used to secure the ends have to fit both the inside and outside of the tube.

Soft tubing is available in both metric and imperial sizes. The typical ID size ranges from 10mm to 13mm and ⅜” to ½”. OD sizes run from 10mm to 19mm and ⅜” to ¾”.

So how do you know what size tubing to use?

We need to consider all aspects of size when answering this question: inside diameter, outside diameter and the combination of both.

- While tubing ID does have an effect on the flow rate of the coolant inside it, the difference between the standard sizes of PC water-cooling tubing is negligible.

- Tubing OD will affect the appearance of your finished build and larger sizes could cause clearance issues with certain water blocks.

- The most important thing to consider in tubing size is the combination of ID and OD. These numbers determine the wall thickness of your tubing, which in turn determines its flexibility and resistance to kinking.

Thinner tubing walls are more flexible than thicker walls and are generally easier to work with.

Thicker tubing walls are more resistant to kinking and collapse but are less flexible and as a result can be more difficult to work with.

In the end, the size of your tubing will be determined by your aesthetic preference and the route of the tubing itself. Short tight bends may not be possible with a thicker-walled tubing for example, while smaller and thinner tubing may sag in longer runs, making it unappealing to the eye.

EK’s ZMT EPDM tubing.

Materials

• PVC

• Polyurethane

• EPDM

• TPV

PVC - The most common material used for flexible tubing is PVC (polyvinyl chloride). PVC strikes a good balance between cost and performance. It offers unmatched clarity and is available in virtually any color you could want.

Polyurethane – Polyurethane tubing is uncommon in the PC water cooling world but is offered by a couple of brands. While there are significant differences in the compounds themselves, for purposed of choice in your PC polyurethane and PVC can be considered equals.

EPDM – An acronym for ethylene-propylene-diene monomer, EPDM is a synthetic rubber that’s flexible and resistant to heat and chemical reaction. While EPDM is essentially maintenance free, it’s completely opaque.

TPV – Thermoplastic vulcanizate, or TPV starts life as EPDM tubing but polypropylene is added in a vulcanizing process. Like polyurethane and PVC, the functional differences between EPDM and TPV in PC water cooling are essentially zero.

Tools

Sharp tubing cutters are essential for clean ends on soft tubing.

Cutters - Specialized cutters are available for flexible tubing. These will give you quick clean cuts in any of the common flexible tubing materials.

Accessories

Anti-kink coils help thinner-walled flexible tube hold its shape.

Anti-Kink Coils - Sometimes soft tubing will kink if it’s put into a bend radius too tight for the material and/or wall thickness of the tubing. Anti-kink coils are available to keep this from happening. Essentially a long spring that wraps around your tubing, these coils provide support to the outer surface of the tube to help it hold its shape.

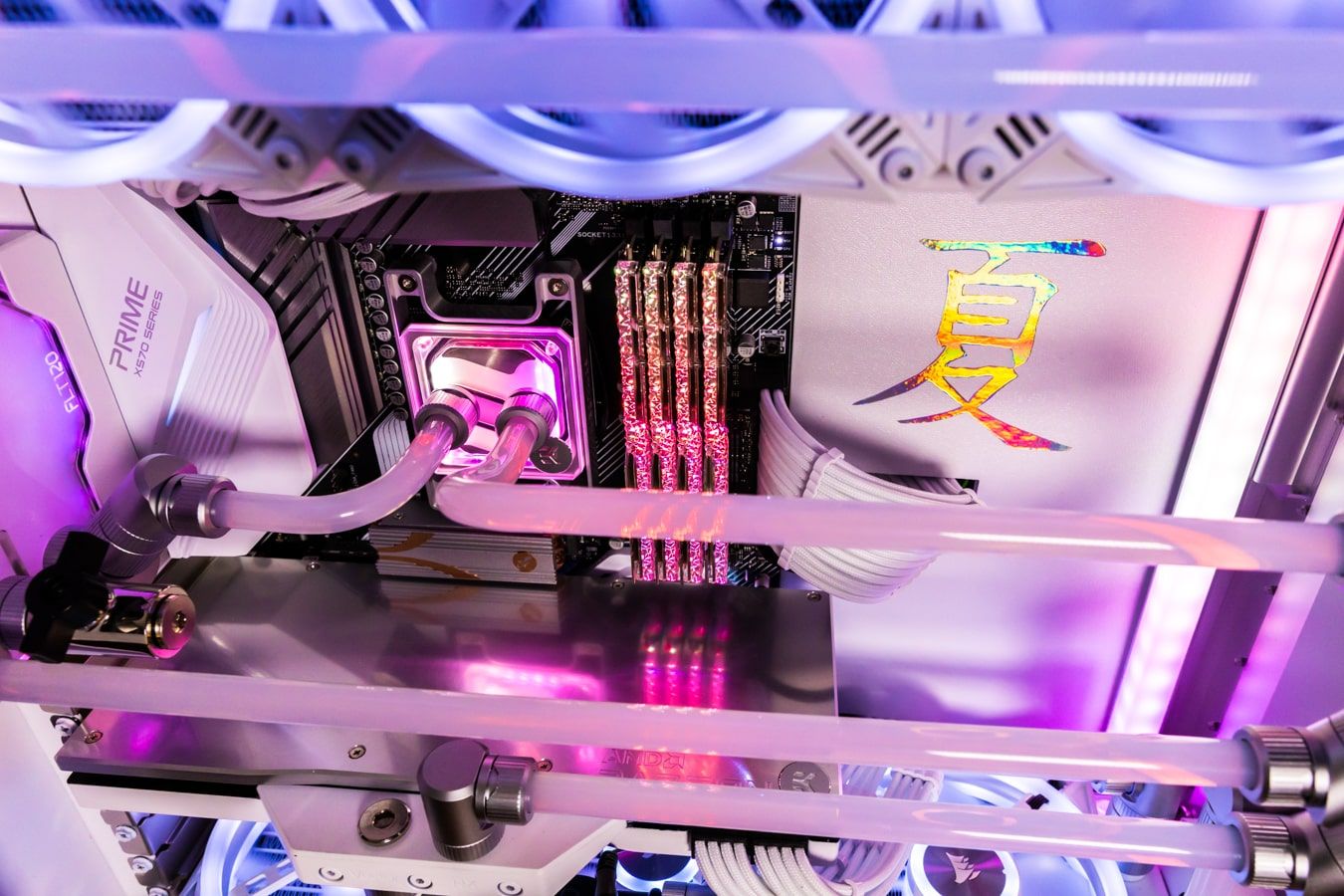

Clean rigid tubing runs in one of our Featured Rigs.

Pros

• Aesthetics

• Supports small loads

Cons

• Difficult to install

• Cost

Rigid tubing is very popular among today’s water coolers. It offers an aesthetic that can’t be achieved any other way. The perfect straight runs, tight-radius bends and even full-circle curves possible with some forms of rigid tube are impressive to see and can make your custom PC stand out visually.

In addition to its appearance, rigid tube will support smaller loads like flow indicators and fittings for temperature sensors and valves without flexing. This can also make for a beautiful clean uncluttered build.

While achieving the clean look that rigid tube is known for is absolutely possible for even the beginning water cooler, it is much more difficult than building the same loop with flexible tube. Bends, angles and tubing lengths have to be considered and planned ahead of time, and the tubing must be bent and cut to exacting specifications.

Rigid tubing is more expensive than flexible tubing. While some of the more common materials like acrylic and PETG come close to the cost of flexible tube, when the specialized fittings needed for rigid tube are added to the calculations rigid tubing is always more expensive than flexible tube – sometimes much more.

Bent, sanded and painted rigid tubing from “Luxe”, another Featured Rig.

Size

While rigid tubing isn’t offered in the same range of sizes available with flexible tube, it does offer one advantage – only the outer diameter of the tube is considered when deciding on size.

With only rare exceptions, the fittings used for flexible tube seal only against the outside of the tube. That means that only that dimension is needed for size reference in general. Common sizes of rigid tube include 12mm, 14mm, 16mm in metric and ½” and ⅝” in imperial sizing.

The inside diameter of rigid tube is important in choosing bending cord for your project. Silicone bending cords are inserted into rigid tube when bending to keep the tube from collapsing. These cords are made for specific diameters of tube, but not all tubing of a given outside diameter will have the same inside diameter. Be sure that the insert you purchase matches the ID of your tube.

Materials

• Acrylic

• PETG

• Brass (coated and bare)

• Glass

• Carbon fiber

Acrylic - One of the two most common types of rigid tube used in PC water cooling, acrylic tubing is available in many different colors and offers clarity surpassed only by glass. It bends easily when properly heated and offers more scratch resistance than PETG.

PETG – Polyethylene terephthalate glycol came into the industry as an easier-to-use and more-flexible replacement for acrylic. Ease of use is too subjective to quantify here but PETG does have a lower melting point than acrylic, allowing it to be bent at lower temperatures.

That same property does make PETG susceptible to deformation both during the bending process and in use in a high-temperature loop. EK and Alphacool both offer special inserts for PETG tubing to support the inside of the tube at the fittings to counteract this, but it’s a drawback that should be considered.

Rigid tubing in combination with an inline temperature gauge in “Evolution” from our Featured Rig series.

Brass – Brass is a soft metal alloy of copper and zinc, making it suitable for use in any copper-based liquid cooling system and offering strength and rigidity only matched by more exotic materials like stainless steel and copper. Raw brass can be bent in much the same way as acrylic or PETG tube and doesn’t require heat to do it, though special tooling is required.

Brass tube can also be purchased with a plating of another metal like nickel or chrome. This tube cannot be bent without cracking the outer plating but can be purchased with preformed bends.

Glass – Glass tube offers unmatched clarity and scratch resistance as well as immunity to almost all chemicals.

Countering those advantages are the brittleness of the material and the difficulty of bending it. While borosilicate glass can be bent, it’s more difficult than bending any other form of tube, and bends that go wrong can’t be re-heated and bent again. Pre-bent pieces of glass tubing are available.

Carbon fiber – A very uncommon material used in PC water cooling, carbon fiber tubing is strong and lightweight, but always opaque and cannot be bent or formed.

Cutters – Fine-toothed hand saws and angle guides are available for cutting most rigid tubing materials with the exception of glass.

Simple tools are often then best solution.

Rotary tubing cutters will make short work of metal tubing and can be used on acrylic and PETG as well, though care must be taken to avoid cracking it with excess pressure.

Rotary cutters are excellent at cutting metal tubing.

Special glass-tubing cutters are made for this difficult material also.

Reamers – When most rigid tubing is cut, a burr is left behind along the inside and/or outside edges of the cut. A reamer is made with two angled cutting faces to remove this burr from both.

Bending Tools – This is an entire category of tools in itself, but it can be broken down into three areas: bending cord, heat guns and mandrels.

Bending cords - Made of silicone for its flexibility and heat resistance. They can be solid or hollow, but all are made for a specific tubing inside diameter. These are inserted into your tubing prior to heating and bending and help the tube hold its shape and avoid kinks.

Bending cord is essential for bending acrylic or PETG tubing.

Heat guns - Simple handheld electrical heaters that blow very hot air are called heat guns. They’re very similar to a hair dryer but operate at much higher temperatures. When you’re looking at heat guns, look for ones with a minimum output of 1500 watts and with a flat back behind the handle – these can stand vertically on their own, freeing both hands to manipulate the tube being heated.

Mandrels – While technically a mandrel is cylindrical, in PC water cooling the term is used to describe a form used to bend rigid tubing, regardless of shape.

Mandrels come in many different shapes, providing forms to bend your tubing into many different angles and even full 360-degree loops and spirals. Some are fixed and provide a single form for bending, while others are adjustable and can be used to make nearly any shape or form with your tubing.

A set of aluminum bending mandrels from Monsoon.

Most mandrels are designed with a curved surface to support your tubing and are designed to fit a specific outside diameter. Be sure that any mandrel you’re considering is designed to work with the tubing diameter you’ve chosen.

Lubricant - A lubricant of some kind is typically needed to insert a bending cord into a piece of tubing prior to bending. While some household oils or soaps can be used, lubricants are made specifically for this purpose.

Different options for lubricant used for inserting bending cord into rigid tube.

Kits - Rigid-tube bending kits are available in several sizes, from simple deburring kits to fully-equipped bending kits that contain every tool we’ve mentioned in multiple sizes. If you’re considering a kit, looking closely at which tools you need to achieve your goal and which tools you can do without can cut the costs on your project.

Alphacool’s Eiskoffer Professional Bending and Measuring Kit

Accessories

PETG tubing inserts – While the lower melting point of PETG makes it slightly easier to bend than acrylic, it can also result in reformation in high-temperature water loops. This is typically seen at the spot where the tube enters a fitting.

PETG inserts support the inside diameter of the tube at the fitting to prevent collapse.

Today’s custom PC water cooling market offers quite a range of options for tubing. Material and size alone make up dozens of options for you the builder. Like many other facets of PC water cooling, tubing selection can be intimidating. We hope this guide helps you in your selection of the perfect tubing for your next custom PC build.