2-Day Expedited Shipping Only $14.95 - See Restrictions

Featured Rig #9 - "Valkyrie" by Haurjie

Hardware:

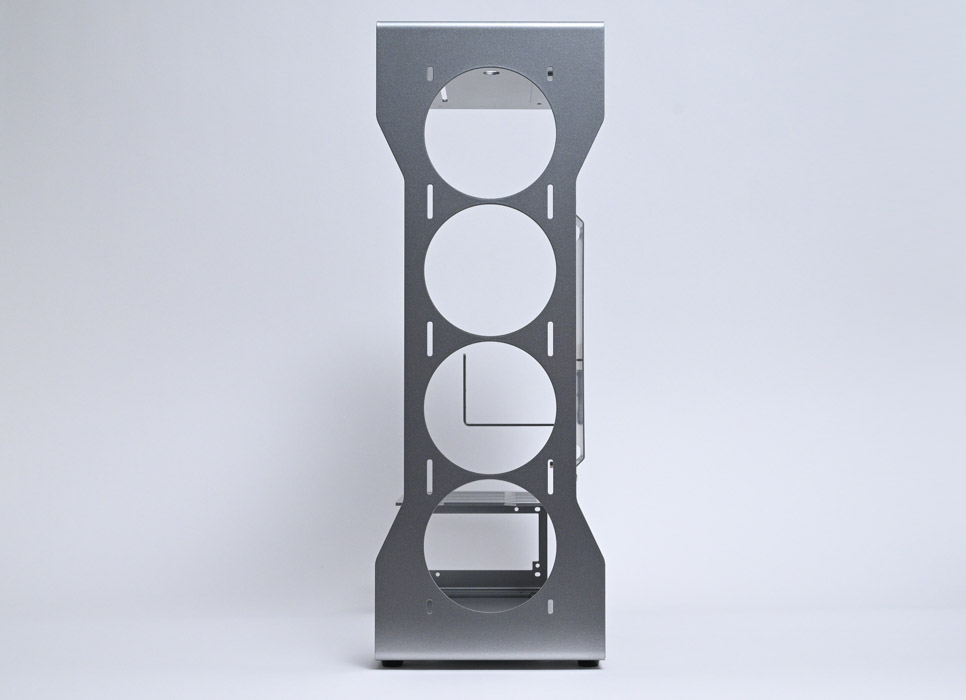

Case: Valkyrie Open Air Water Cooling Case

CPU: Intel i9 13900K

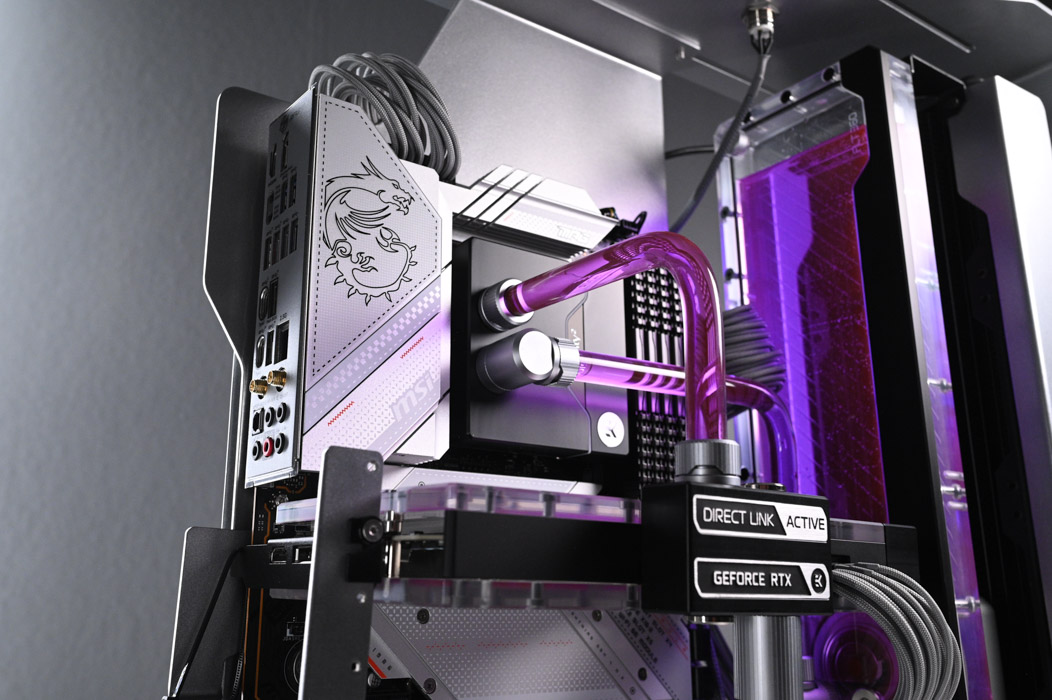

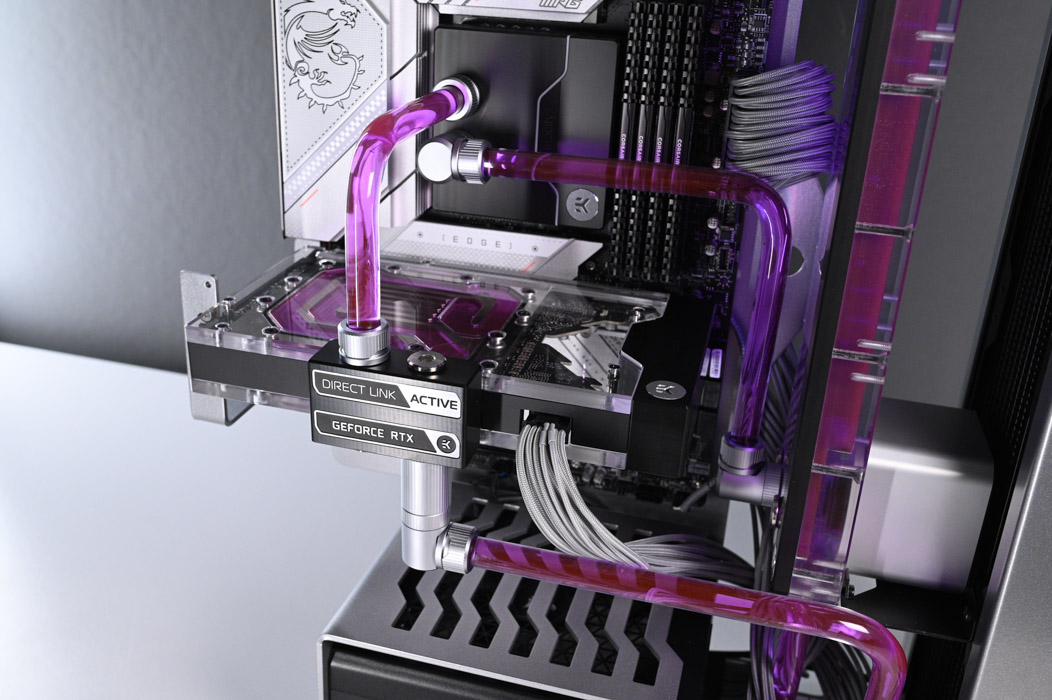

GPU: Nvidia RTX 4090 Founders Edition

Motherboard: MSI Z790 Gaming Edge WiFi DDR4

Memory: 64GB Corsair LPX Vengeance 4000MHz

SSD #1: Samsung 980 Pro 2TB

SSD #2: Samsung 970 EVO Plus 2TB

Water Cooling Components:

CPU Waterblock: EKWB EK-Quantum Velocity 2 LGA 1700, Nickel/Acetal

GPU Waterblock: EKWB EK-Quantum Vector 2 FE RTX 4090 With Active Backplate, Nickel/Plexi

Compression Fittings: (8) EKWB EK-Quantum Torque HDC-14, Satin Titanium

Fitting Adapters:

(3) EKWB EK-Quantum Torque 90 Degree Rotary Fitting, Satin Titanium

(2) EKWB EK-Quantum Torque 45 Degree Rotary Fitting, Satin Titanium

(1) EKWB EK-Quantum Torque Static MF 28mm Extension Fitting, Satin Titanium

(1) EKWB EK-Quantum Torque Static MF 7mm Extension Fitting, Satin Titanium

(1) EKWB EK-Quantum Torque T-splitter 3x Female Ports Fitting, Satin Titanium

(1) EKWB EK-Quantum Torque Rotary MM 14mm Extension Fitting, Satin Titanium

(2) EKWB EK-Quantum Torque micro plug fitting, Satin Titanium

Tubing: EKWB EK-Loop Acrylic 14mm OD Hard Tube

Pump/Reservior Combo: EKWB EK-Quantum Kinetic D5 FLT360 with add-on EKWB EK-Quantum Convection D5 Pump Cover, Silver

Radiator: Hardware Labs Black Ice Nemesis 480GTX

Fans: Noctua NF-A12x25 fans

Fan Shroud/Grill: MNPC Tech 480 Overkill fan grill (custom made)

Valkyrie Video From Haurjie:

Valkyrie Case Design Q&A:

I love the design of this case! What have you decided to name it?

It is called Valkyrie. Coming up with names, titles, and logos has always been one of the more difficult things to do when it comes to branding and marketing because you have to think very long term and how it sticks. I’ve had several occasions in the past where I was excited about an idea or a name only to find it out it’s either already taken or I just ended up changing it more than once later down the line because I didn’t like it as much as I thought. I’ve been doing tech content on YouTube and social media for about five years now and it took me two years to come up with the channel logo and to this day I still haven’t figured out a channel name yet, so the temporary working title is still just using my first name, Haurjie.

During the early stages of designing, I had talked with several people to get feedback on and one of those people was Brett from UFD Tech, he had made a comment over our Discord video session that it “looked like a spaceship.” Funny enough, right before the chat, I was playing one of my personal favorite games, StarCraft 2. Brett’s spaceship comment reminded me of the Terran Viking unit in game, and that immediately became a top choice for the case name. But something just didn’t hit right with naming the case “Viking”, so I thought about the Protoss Corsair unit and the Terran Valkyrie, ultimately, Valkyrie sounded the best.

Well it’s an amazing piece of hardware. As a longtime fan of bigger cases, I’ve been kind of disappointed to see most of these kinds of open-air cases made for the mini-ITX crowd. Yours is a full-sized design.

What made you decide to go that way instead of the more common SFF route?

I love SFF builds and it has especially become very trendy in the past few years. When you think about technology in general, the goal really is to make things fast, stronger, more powerful in a more compact form that is easy to carry and takes up less space so I think this is really where the future is heading. For me personally, it’s not really so much about ATX vs ITX, but rather just making it open-air.

The answer to why I made this ATX is simple, I just wanted more USB ports on my motherboard as I was coming off of using a couple ITX builds for a while and I didn’t like using hubs. I’m still 50/50 about the hubs, depends how good the hub is. I wanted the case to be open-air and also full steel for better durability and less restrictive on air flow and thermals and have enough ports for direct connection to the motherboard.

Looking at your pics I can’t tell if the case is made from stainless steel or aluminum. Which is it and why did you opt for that material?

It’s made of raw thick steel. It can be made of stainless steel as well, in fact the very first prototype I did was stainless steel, but raw steel was more economical and better for painting. Yuel Beast actually set the standard for me on this, Eric over there is an amazing guy and designed his cases really well. When I first jumped on the Motif Monument back in 2020, that was my first experience of using an open-air case and first-hand feeling the weight of a full thick steel chassis, that was when I knew I couldn’t go back to the generic thin flimsy aluminum cases that every big tech company fabricates and mass produces in China. Open-air is the way, thick steel chassis is the way.

In your video you list both the Mobius case by Yuel Beast and the “Ares” build by Alessandro Zaiti at Explore Modding as your inspiration for the Valkyrie. Those two set the bar pretty high but I have to say you pulled it off.

What was it about those cases that inspired you?

The Yuel Beast Mobius is my favorite mini-ITX case and I love the aesthetic design of it. When I decided to change my desktop setup and upgrade my main rig, I wanted to use more power-hungry parts that the Mobius wasn’t quite thermally designed for as it can’t mount too many radiators or larger radiators. I really liked the front face of the Mobius and I literally took that and shaped the rest myself.

Alessandro’s build was the one that gave me the idea of flipping the motherboard tray. I’m sure there are other builds out there that did the same thing perhaps, but his was the one I just happened to land on and seen for the first time. I liked that idea and wanted to provide that flexibility in my design. The only difference is the way the ARES was designed would and does require more complex mechanisms that wouldn’t make sense economically if I were to try and produce multiple units. So, I took a more simple route where you could flip the tray, slide it back and forth for adjustments and that would be set.

What sort of CAD software do you use in your design work?

I use a free source called OnShape. It’s a website and the program was designed by the same people who made Solidworks.

Any suggestions along that line for any of our readers who might be wanting to get into CAD?

There are a lot of CAD programs out there but start simple and be resourceful if you’re just starting this off as a hobby, if you already have access to a full license software like Solidworks or Fusion 360 then great (those are expensive), but try not to spend too much in the early stages and really just learn as much as you can first. YouTube is also the best teacher.

Once you came up with the design and had each piece modeled, how did you go about turning those models into reality?

Learning CAD and 3D modeling was one thing, but learning actual sheet metal fabrication and the manufacturing process logistics was something completely different. There were and are designs I want to do, but reality is that machines like press brakes and such are not capable of doing certain procedures so in the early stages of designing and submitting my files to the shop, I had quickly learned how to change my design thought processes knowing these mechanical limitations. From there it was just simply design, submit, and order.

It seems like most newer chassis are trying to be everything for everyone – they provide a lot of options in radiator size and mounting positions, pump mounts, and some newer designs even let you adjust or modify the case itself.

Yours is a very strict and simple design without a lot of options for components outside the list it was made for. What made you take that route?

That’s a very good question. So, there are a couple things, first is really because I love the Mobius case a lot and I decided to just make a bigger version of it with my own spin. The Mobius only has certain mounting spots for certain components, but I would say that’s mostly because mini-ITX cases usually aren’t designed for high modularity anyways as you are limited on space.

Second is, yes, some cases (old and new) provide a higher level of modularity and flexibility. But if you really think about it, let’s take a common ATX case like the O11D from LianLi, it’s a great case and I’ve owned two versions of it myself (normal and the mini) in the past as my main rigs, although there are multiple mounting options for certain components like cooling hardware, just because people have the option to put certain things in many places doesn’t necessarily mean they will. The O11D is a great example because it was very popular and there are a ton of build samples to pull data from. When you look at how people generally build, although given various mounting options, people will still tend to only mount certain things in certain places because it is either thermally optimal that way or it just looks the best to them that way or both. And these “flexible placement varieties” really aren’t even that many, it’s like maybe two options for each certain hardware and that’s it.

And if you think how people shop for cases, they will pick a case based on their core components and want to max out the case’s mounting potential that fits their needs. You don’t buy an O11D XL or a Corsair 5000D and say yeah look at how much room and flexibility I have and I can use multiple 240mm radiators in these 360mm slots and slide them up or down, yay! You just don’t do that. You would say, I need two 360mm radiators for my build here, I’ll go with the Corsair 5000D which allows me to mount one 360mm radiator each for CPU and GPU, and another panel to hold exhaust or intake fans, that’s it.

Another truth is if user wants to upgrade and rebuild their rig, they don’t usually change mounting positions on certain hardware just because they can either, they’re typically going to leave them as is because they have already thought of what was thermally optimal and visually aesthetic for them.

Although aesthetics is subjective, you will see there is a consensus to where people think things are best placed. You can pull up any case build and grab a decent sample size data, you’ll notice there is a majority of where people like to place the pump/res, where people like to place certain size radiators etc.

For the Valkyrie, going back to my first answer for this question, although it is ATX and not ITX, it does have room for modularity if I wanted to, but that also means I would have to design the case much more exact to the Mobius itself. I don’t want to COPY the Mobius, I just want to pull inspiration from it. And even if I did make an exact ATX version of the Mobius somehow, I would still pick the same mounting positions as I did in my Mobius build itself which going back to my second answer, because it’s what I think is aesthetically and thermally optimal.

I intentionally wanted to just “keep it simple,” I will also say that I do have some more modular designs in my head and I’ll be playing around with those on future case designs.

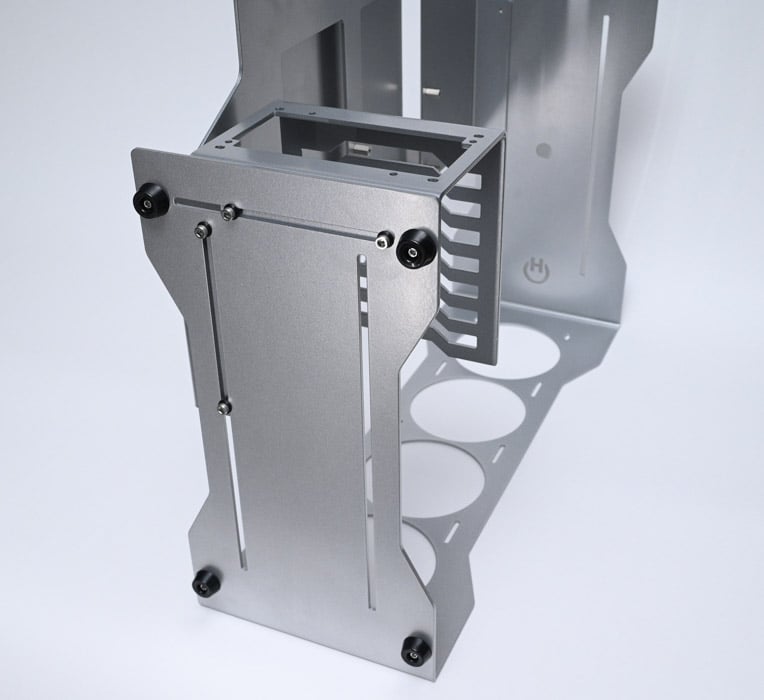

The adjustable PSU bracket and motherboard tray are excellent additions. How much movement is possible with each?

Motherboard tray can slide back and forth up to 145mm. But I also don’t expect anyone to really side that motherboard tray all the way to the front either because of physical clearance involving the motherboard itself with cooling hardware mounted to the front.

PSU bracket slides side to side up to 40mm, this is to accommodate more clearance depending on whether you want left or right sided motherboard tray configuration.

If the case is made with very specific components in mind, why the need for the adjustability?

Specific components would refer to for example, ATX size motherboard (You can still use ITX motherboard if you want) and 480mm sized radiator (you can still use smaller radiators if you want). The adjustability is really meant to accommodate different sized GPU blocks and thicknesses of radiators and fans. An RTX 4090 Founders Edition waterblock is not going to be the same length as an ASUS 4090 waterblock. An EK 3080 waterblock is not the same size as a Corsair HydroX 3080 waterblock. Then there are also various radiator thicknesses and a standard 25mm thick fan vs if you want to use something like Phanteks T30 fans that are 30mm. There is also the possibility if someone wanted to place the fans on the outside of the front panel and radiator inside, or maybe both on the outside? So, it’s really meant to fine tune certain fitments like that.

The symmetry of the Valkyrie is beautiful and not just for aesthetics. What does vertical symmetry like this do for the user?

Vertical symmetry was important for what side of the case is facing the user. You can certainly build a case with the right side configuration and set it to the left of your desk, but you’d be looking at the blank back panel all day… I mean nothing wrong with that if that’s what you want, but I want people to have the beauty of the exposed side where you see all the components facing the user.

Open-air cases typically offer little to nothing in the way of support for cable management. Does the design of the Valkyrie have any provisions for hiding the inevitable wires we need in our machines?

Yes that issue is absolutely given in an open-air case, I do find that somewhat of a fun challenge as a PC modder and builder myself. The truth is that it is difficult and I think some cables you just can hide, but rather the goal then is to either minimize the cables or if you are creative, route the cables in an artful and tasteful way. A very similar example I’d like to make is if you ever seen the massive loads and traffics of cables inside a server room, those can either look like a nightmare or an art work. Just Google it. Another one is if you’re into the custom keyboard hobby, custom coiled cables and LEMO quick disconnect cables aren’t eyesores on the desk, they are very beautiful crafted cables that are pretty pricey too.

In the Valkyrie, I added something optional called radiator wings or guards where the purpose is to hide the side of the fans and radiator to make it look cleaner and smoother, but also allows the fan cables running off the side to be more hidden and routed in a way that hugs the top and bottom of the case frame as opposed to having them just run straight across the middle of the case. This was my answer to the same problem I ran into when building my Mobius, there was nothing to hide the fan cables running across the back side.

Just a disclaimer, the radiator wings were only designed for 480mm radiators with certain thicknesses (54mm and above), and if you mount both the fans and radiator together on the same side. In my personal build, I have Hardware Labs Black Ice 480GTX Nemesis and standard size Noctua NF-A12x25 fans as the example.

Valkyrie Build Q&A:

Wow, amazing end product! The first thing that strikes me is the front fan grill. That really makes a statement! Can you tell me a little about that?

The front face of the rig is what has been getting a lot more compliments to no surprise. Bill from MNPCTech did a really good job on his Overkill Ring fan grills and it’s really hard for me not to use it. I’ve used the 240mm and 360mm version in past builds and they always turned out nice, but here we stepped up with the 480mm and it is… overkill. My friend Derek (RhoadsPC), who’s also a fellow PC modder and someone who I competed against in the last Intel Creator Challenge a couple months ago said “powerful front end, that’s for sure.”

The overall build has a monochrome look, but that really makes your coolant stand out. What coolant did you decide on?

I always use clear or transparent coolant for low maintenance purposes. Most of my projects I always use Corsair’s XL8 (formerly XL5) in my personal or client builds. There were a few times where I also used EK’s transparent coolants as well. But I really like Corsair’s HydroX coolant because you can go on for two years without having to change it, that’s how long I’ve had my last rig go for and it’s still clean.

Your fitting choice is a perfect match for the bare steel material of the case. Do you plan to offer the Valkyrie in any other colors?

Yeah the fittings were either going to be the shiny nickel or the stain titanium from EK, because of the matte tone of the case which I powder-coated in silver, it matched perfectly. Valkyrie gets offered in black, silver or just raw steel for people who want to paint their own.

That looks like a super long cable run from the top of the motherboard down to the power supply. How long do these need to be for someone building in the Valkyrie?

Now that I have it done, I will tell you what the cable lengths I wish I had gotten instead of what I actually got because I think some of the cables would be better if they were longer.

EPS: 94cm

24-pin: 70cm

PCIe: 70cm

SATA: 40cm

Seeing the rear wire management plate in the back in use I can see why you included it. It really cleans up that side of the whole machine. Is that panel the same thickness and material as the rest of the Valkyrie?

No, the back cover panel is one of the thinner ones, just like the optional radiator guards which are the same thickness. Only the main frame, motherboard tray, PSU bracket and GPU arm are thicker.

As a long-time modder, one thing I love about the Valkyrie’s overall design is its “blank canvas” appeal. Even being as purpose-made as it is, all that clean blank steel is begging for drills and taps and custom additions. Are there currently any plans to offer accessory pieces for the case?

That’s a very good question. In the earlier designs of the Valkyrie, I actually had an auxiliary bracket made to be able to add on to secure onto the same sliding slots of the motherboard tray in case someone wanted extra mounting options. But when I got those in and tried it on, it was a bit too crammed and it would force the user to use thinner radiators or place certain hardware in places that were less optimal. And it just made the build look hideous too. So it brought me back to the drawing board reminding me why I designed it, both for function and aesthetics it’s better without it. So as of right now, the answer is no. But I also anticipate the small niche of people this case attracts are probably going to be people who are either experienced with water-cooling and/or have some level of modding skills themselves, if they want something that I don’t offer, I bet you they’ll find a way, because that’s how we do it.

What is the noise level like? Noctua fans are famously silent but you’ve got a lot of radiator fins in that space. Does the open-air nature of the build make it louder than you might see with a closed case?

I currently have my pump and all four fans set to 60% speed, and the decibel meter readings top out at 43dB. Running everything at 50% brings it down to about 35dB and even that is enough to keep everything cool.

Open-air cases CAN be louder than closed-cases, but it’s not necessarily the case. I’ve had closed cases be louder with the same cooling hardware and fan curves simply because of how the filters and ventilations were designed and cut. For example, if you have airflow running through all those small little holes on filters and vent panels, it changes the sound profile of airflow as opposed to no obstruction like open-air cases. Similar to if you were to blow air with a wide-open mouth vs narrow down your lips to a whistle. But generally speaking, the difference is actually not that big at all.