2-Day Expedited Shipping Only $14.95 - See Restrictions

Water Cooling Components - Specialty Fittings

Welcome back to the Component Series. We hope to help builders both new and old to understand their options when it comes to the components in their custom water loops. In today’s entry we’re taking a look the most unusual fittings you can add to your arsenal: specialty fittings.

Specialty fittings is a wide category. As the name implies, each fitting has a special purpose – something not able to be done with any of the more standard fitting types.

Let’s take a look at each type of specialty fitting and how they can help you with your custom water cooling system.

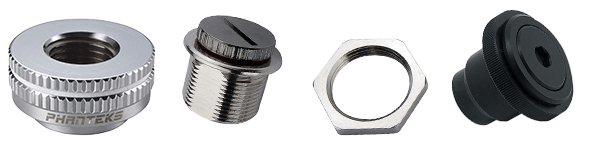

Fill Ports & Passthroughs

Fill ports (also known as bulkhead fittings) provide a way to install a standard G1/4” female port just about anywhere. The have two sets of threads – G1/4” inside and a larger thread outside. This outer thread can vary between fittings, but fill ports will also come with a nut that matches this outside thread.

To use a fill port, a hole has to me made (or already present) the size of the diameter of the outer thread. The fitting is placed through the hole and the nut is installed on the back side, holding it firmly in place. In the end you’ll have a female G1/4” port on either side of the panel that the fitting is installed in.

Fill ports are useful not only in a top panel to aid in filling but also in vertical panels as secure passthroughs for your coolant.

If you’re routing your tubing to the outside of your PC’s chassis, passthrough fittings also come in a ready-made configuration that doesn’t require any holes to be drilled. These are made to fit into an unused PCI slot on your case and include pre-installed G1/4” female fittings.

Valves

When talking about specialty fittings there are a couple of different kinds of valves, but the most common is the drain valve. These are ball valves that are typically installed in a low spot on a custom water loop to allow the coolant to be drained when needed.

The most common type of drain valve has a handle that turns the ball inside it to control flow. These can have male or female ends and those ends can be fixed or rotary.

Another type of drain valve is the sliding valve. These serve the same function but instead of turning a handle to open or close the valve, a portion of the fitting itself slides to control the valve’s position. These offer an advantage over the standard ball valve in space savings and having to orient the handle for access.

LED

LED fittings are used to bring illumination to different parts of your custom water loop. They come in two forms: plugs and collars.

LED plugs fit into standard female G1/4” ports and shine light through the port. These are typically used in reservoirs to illuminate the coolant inside, but there are also fittings made to use these to shine light through the tubing itself. These LED fittings can be found with LEDs included and pre-installed or as a standalone plug with a pocket made into it to fit a specific size of individual LED.

LED collars fit over your tubing and have an internal ring of LEDs that light up the coolant inside.

Flow Indicators & Flow Meters

These specialty fittings are made to show and/or measure the flow of coolant in your cooling loop.

Flow indicators are visual devices that provide clear and simple visual indication that coolant is flowing. They consist of a block of some sort with at least two G1/4” ports and clear sides, and a motion component inside. Typically this is a paddle-wheel shape, but there are other shapes on the market. This motion component spins in place as the coolant flows past it, giving instant visual feedback on whether the coolant is flowing or not and to some minor extent the relative speed of the coolant.

Flow meters are much more complex devices that actually measure coolant flow electronically and either display that data directly or send it to an external piece of hardware.

Thermal Sensors

Thermal sensor fittings are exactly what the name implies: fittings with thermal sensors built in. They’re made to be inserted into your cooling loop and connected to external hardware of some kind like a controller or a gauge. They can be found as simple male plugs or as passthrough fittings with two female ports.

Down Tubes

Some the simplest of the specialty fittings, down tubes are installed on the inside of the intake port of a reservoir. They serve to channel the incoming coolant so that it exits the tube beneath the surface of the coolant in the reservoir, eliminating splashing and potential introduction of air into your cooling system.

Anti-Cyclone

If you have a pump with a high flow rate, a small reservoir or both, it’s possible for your system to develop what’s known as a cyclone. When this happens, the suction from your pump creates a whirlpool effect in your coolant. If this whirlpool is large enough, air can be drawn into your pump.

Anti-cyclone fittings are designed to be installed in the inside of your reservoir in the outlet port. Once installed they break up the flow of coolant to that port, preventing any cyclones formed from reaching far enough to introduce air into the rest of the cooling system.

Filters

Filter fittings are self-explanatory, serving to filter out debris and foreign materials from your cooling system. Most share the same form factor: a small cylinder with a female port on each end. They contain a screen of some sort inside, with different filters providing more or less filtration based on the size of the holes in the screen. Many filter fittings will also have a clear viewing window. Filter fittings are designed to be disassembled to access and clean the screen inside as needed.

One filter fitting in particular is different. Offered by Aquacomputer, it comes with a large square viewing area made to be visible from outside the case and has two shutoff valves built in , making cleaning easy.

Disconnects

Disconnect fittings are made to allow you to disconnect portions of your cooling system without draining the coolant. They’re made to work in pairs, one male and one female. Each fitting has two seals inside: one to seal against the other fitting and one mounted on a spring-loaded piston.

When the two fittings are connected together that piston is pressed inward, opening a pathway for your coolant. When disconnected the piston retracts and seals the coolant inside.

Disconnect fittings are excellent for people who move or work in their system often and for external radiator setups.

SLI & Crossfire

While modern GPU power has made systems with multiple graphics cards less common, there are still plenty of builders out there that are getting the most use out of their older cards by using two or even three in tandem. Connecting these to a water-cooling loop can be a challenge.

With the configuration of PCIe slots being different between motherboard models, the spacing between multiple video cards isn’t a constant or easily predictable value.

SLI and Crossfire specialty fittings are adjustable-length fittings with male G1/4” threads on each end. The adjustability of the fittings allows builders to make up any differences in spacing between the water blocks on their video cards.

Air Exhaust

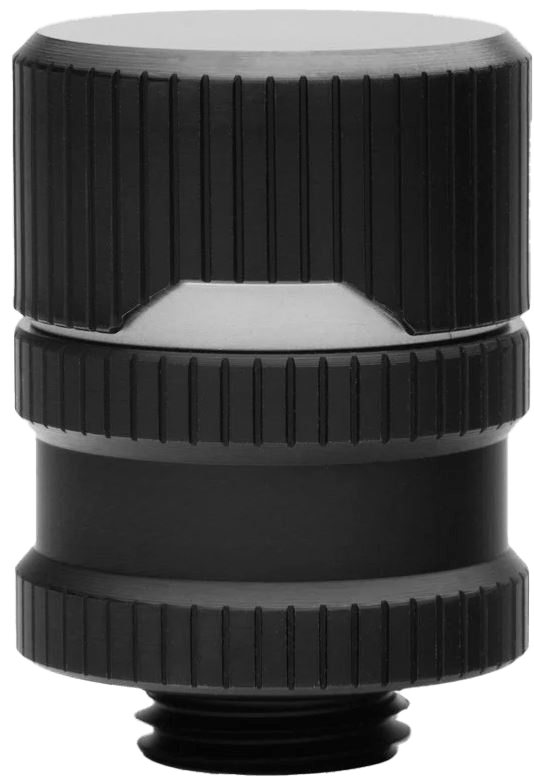

Air exhaust fittings are made to vent excess air within your water cooling system. They come in both manual and automatic versions, both working on the same principal of spring pressure vs air pressure.

Automatic air exhaust fittings have a spring-loaded piston inside with a seal on the bottom and the spring on the top. When air pressure gets high enough to overcome the spring pressure, the piston is forced upward and air escapes until it’s too low to hold the piston open any longer and it closes.

Manual air exhaust fittings work in reverse. They have a seal at the top and the spring at the bottom. They will not open regardless of the air pressure inside. The piston has to be manually pressed inward to open the valve and allow air to pass through one way or the other.

Manual air fittings are excellent additions to a water loop. When placed at the top portion of the loop they can be used to help with the initial air bleeding process by providing a place for air to escape, and they can also help with draining by allowing air to enter the loop as coolant is draining, preventing vapor lock.

Check Valves

Check valve fittings are one-way valves. They will permit coolant to flow through them in one direction but not the other. They can be useful in a water cooling system to prevent backflow during the filling process.

Specialty fittings are… special. They serve very specific needs and do things that no other fitting is able to do. We hope that explaining the uses of each type helps in deciding which one will solve your needs.