2-Day Expedited Shipping Only $14.95 - See Restrictions

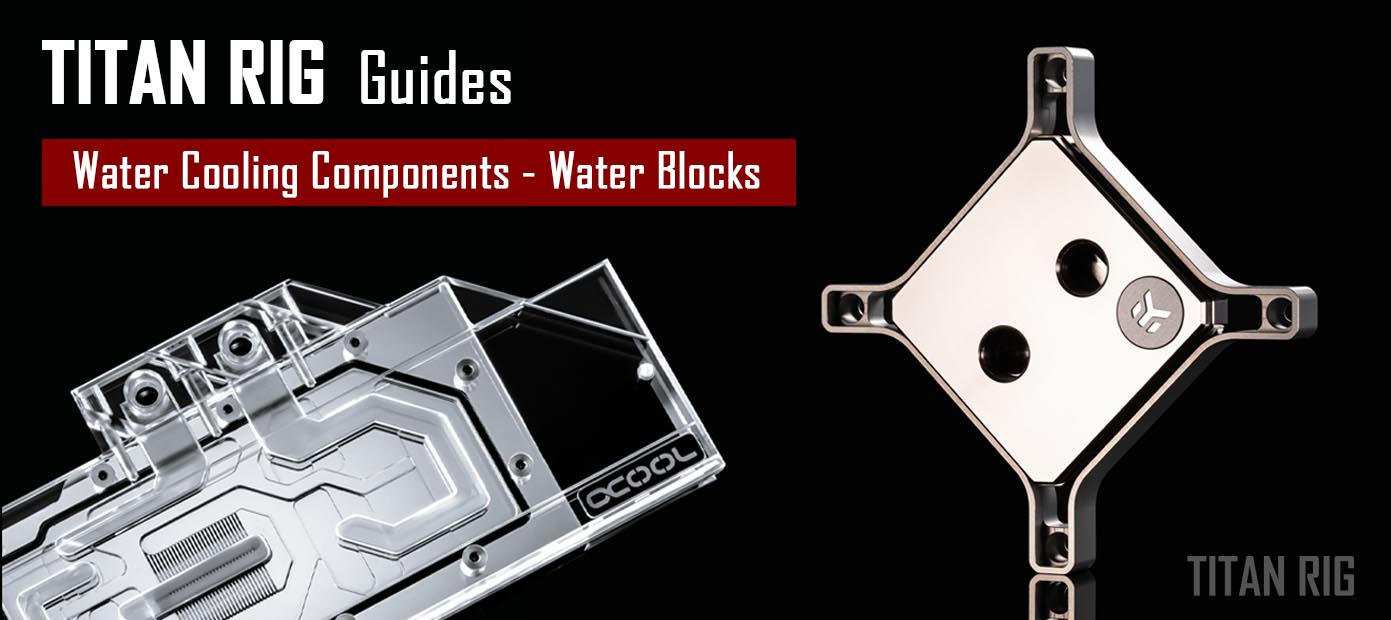

Water Cooling Components - Water Blocks

Welcome to the first installment of our Component Series. In this series we’ll be covering the major components of a custom water loop – what they are, what they do, differences in materials, size, power and function, and how to choose the right one for your rig.

Our first installment focuses on one of the workhorses of your custom cooling system: the water block.

A custom PC water cooling loop serves a single primary purpose: to move heat from parts of your PC to the ambient air around it. While that purpose may be singular, it takes many different parts to make it work. Water blocks, pumps, reservoirs, radiators, fans, tubing and fittings all work together to achieve the goal. The front line of that team is the water block.

Water blocks remain in direct contact with the heat-producing component and absorb that heat and transfer it to the PC coolant, protecting the component in question from dying a fiery death.

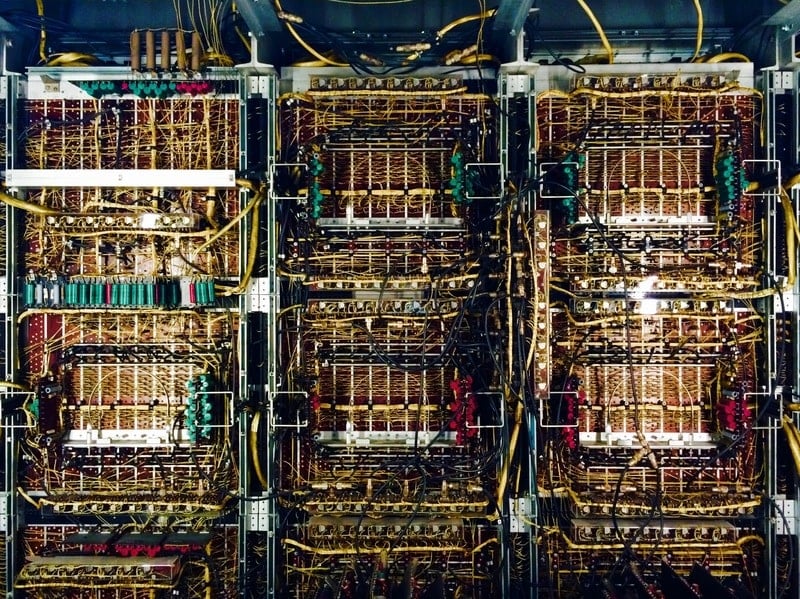

Modern water blocks are the result of decades of research and innovation. One of the first examples of liquid cooling used in a processing unit was in UNIVAC 1 in 1951. Well before the transistor was commercially viable, it used vacuum tubes instead. Over five thousand of them, some with their own water-cooling interface (the predecessor of the water blocks we have now) and some interfaced with the water in groups. It required a 123kW air conditioning unit to chill the 158 gallons of water per minute that were flowing through the system. Warning – graphic and/or disturbing imagery ahead.

An inside look at a section of the UNIVAC 1 processing center. Vacuum tubes were cooled with chilled water.

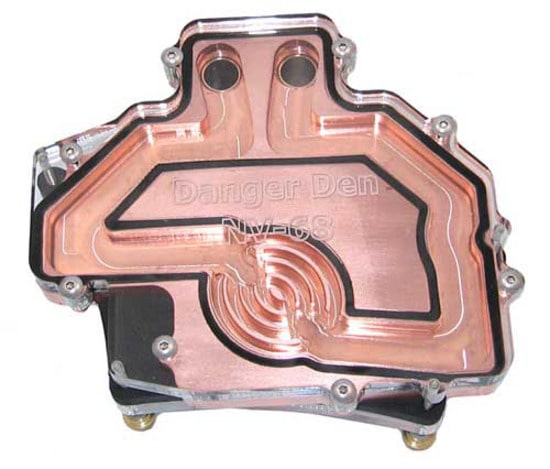

Seventy years ago that computing center required personnel to climb ladders and walk inside it for maintenance. Today we have processors that are smaller than a playing card and have almost 40 billion transistors inside. Cooling technology has kept pace with the industry, giving us the amazingly efficient water blocks of today. I’ve personally watched and participated in the liquid-cooling evolution of the PC over the last 20 years. From the basic machined copper block offered by Danger Den to the rise of factory kits like Thermaltake’s Bigwater series to the advent of All-In-One coolers from Asetek (like the first Corsair H50). Watching technology advance like this is amazing.

Universal GPU water blocks from Danger Den and Koolance. Image credits: Koolance and Danger Den

Advancement often allows for more options and liquid cooling is no exception. There are hundreds of different water blocks available to us as builders today, made for just about any heat-producing component in your PC. They come in different materials for both the base and the top. They have different methods of routing the coolant through them and forcing as much heat transfer as possible. Some are designed to accept add-on LED lighting and some even offer built-in addressable digital RGB.

In this maze of options, how do you decide which water block is best for you? Whether you’re looking for a water block for your CPU, GPU or some other load like VRMs or chipsets, all water blocks have a few things in common. We’ve got articles coming up on specific water block types, but for now let’s look at the things that they all share.

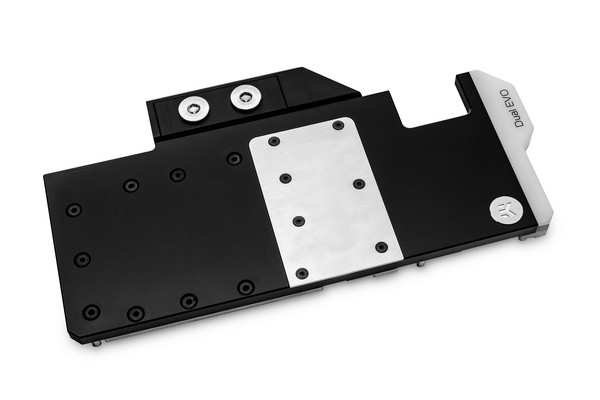

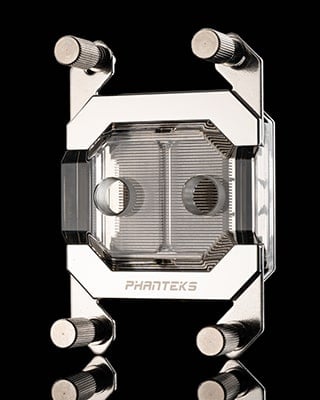

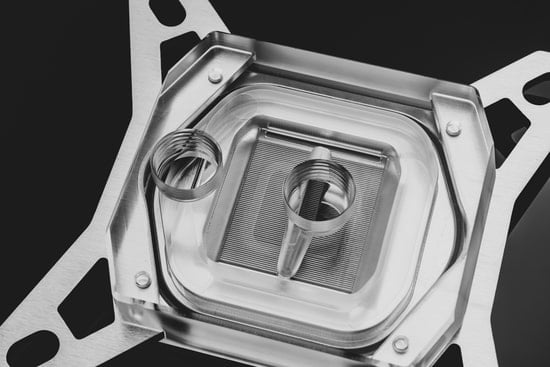

CPU water blocks made with bare and nickel-plated copper, nickel-plated steel, acetal and acrylic.

Materials

While most water blocks have bases made from copper (raw or nickel plated), there are aluminum water blocks available for purchase. The cooling characteristics of these two metals are close enough that performance in a PC cooling system is effectively equal. The choice of which to use is easy though - if every other component of your water cooling system is aluminum then use an aluminum water block. Otherwise copper is the right choice. Never mix aluminum and copper in your custom water loop. Without going too deeply into the science behind it, these metals will react with one another in a water loop, causing galvanic corrosion and potential blockage of high-restriction areas like the fins on water blocks.

While the base portion of water blocks is only found in these two materials, blocks are available with their top portion made from a few different materials. The most common by far are metal (copper, aluminum or brass), acrylic and acetal (POM). Each has their own benefits and drawbacks.

These CPU water blocks from Phanteks and Watercool clearly show the microfin water passages that transfer the heat to the passing coolant.

● Copper and aluminum are the strongest option by far, and they can aid in heat transfer as they offer more surface area in contact with the cooling liquid.

Both copper and aluminum are subject to oxidation and discoloration simply from humidity in the ambient air. They are also obviously opaque, minimizing lighting options. Some are made in combination with acrylic elements like logos and lighting strips, but without those lighting isn’t an option.

● Acrylic offers moderate strength and a clear view of the internal workings of the water block. Being crystal clear, it can be illuminated in many ways also.

While acrylic is fairly strong, it’s also brittle. Overtightening a fastener or fitting in threaded acrylic can cause stress cracks. Cleaning acrylic with alcohol can also cause microfractures called crazing.

● Acetal, or POM, is very durable and will not easily crack or discolor. It’s also immune to most chemicals so cleaning is easy.

Acetal is soft, making it much easier to damage threads by overtightening or cross threading. It’s also opaque, so illumination options are limited in the same way as metal blocks.

Note: Delrin is a brand name for a different polymer of POM. It offers greater strength and stiffness and is less susceptible to accidental physical damage. The name is sometimes used incorrectly when referring to standard acetal/POM though – if in doubt ask the retailer which it’s made of.

Full-coverage water blocks offer the most thorough cooling and best overall performance.

Cooling Performance

Not all water blocks are created equal. All of the research and advances in water cooling blocks and heat transfer over the years have given us some very complex configurations of microfins, jet plates, contact surface geometry – more factors than most people know. Most of these innovations are invisible to the eye and don’t even come into consideration in terms of aesthetics, so performance is king here.

Thankfully, the PC enthusiast community is larger and more interactive than ever. If you’re on the fence about choosing a specific water block, look for testing results online. It’s a narrow niche we’re part of but we share a wealth of information among the community. Thermal testing is done and shared all the time.

These tests don’t have to be professional either. Simple individual users share their experience in product reviews on retail and reseller sites and on social media. If you can find reference to a specific product in a few places you’ll likely see a trend in how it performed in real-world testing.

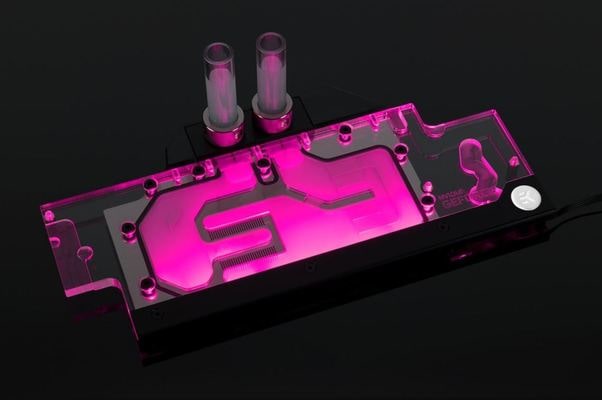

RGB lighting makes these water blocks stand out and is customizable to your PC.

Aesthetics

This factor is always different for every user, and suggestions here are largely pointless. What I like may well be something you don’t like at all. Polished copper, brushed stainless, black or white acetal, crystal clear acrylic, mounting hardware in different colors and finishes – it’s all there and what you like is up to you. Water cooling brands are aware of that too, and many offer a range of materials and appearances in their product lineup.

If you want to light your water block, you have fewer options but it’s still a huge range. Many water blocks today have RGB LEDs built in, while others have sockets machined into them to install individual LEDs of the user’s choice. Again, this is all in how you want to go about it.

There are a couple if things to consider on the side of aesthetics that go along with materials.

A polished metal water block will likely retain its shine longer than any other material, requiring less maintenance to keep that pristine look. Polishing these with a metal polish that leaves a protective deposit will keep them shiny in a closed PC environment for years.

Acrylic and acetal are both prone to mild static buildup. Not enough to harm any electronics but certainly enough to attract every dust particle in your case. Without good filtration these will require frequent dustings or blasts of air to keep them looking new, especially darker colors.

Cost

Water blocks of all kinds have a wide price range to consider also. Cost is almost always a factor in any purchase. Thankfully just about all of the factors listed above are available in the entire range of cost so you’ll likely be able to match up the rest of the puzzle pieces within your budget.